More info on the project

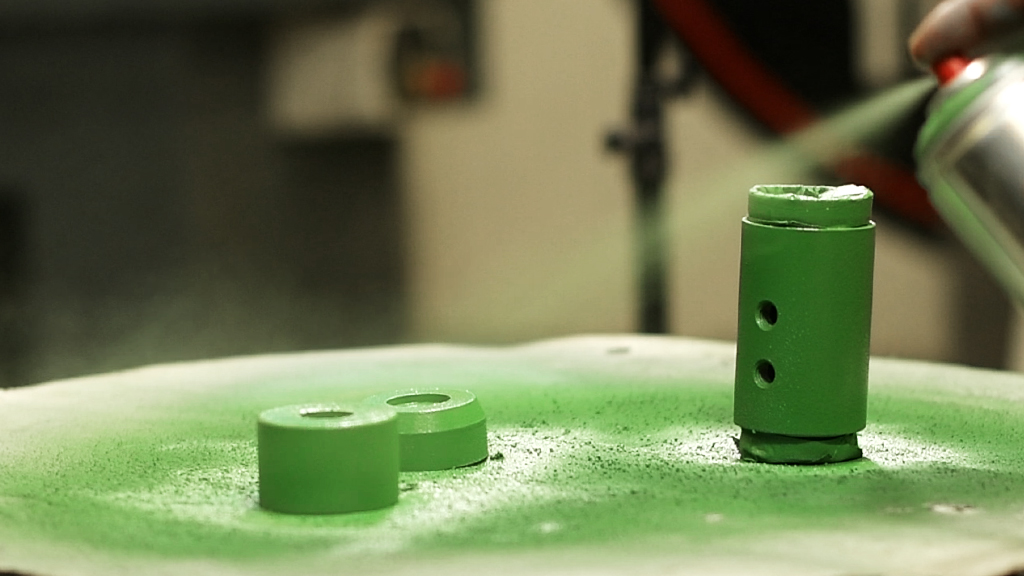

There are many times that we need to screw two thin objects together and we are unable to make a fold due to their thin width. The solution to this problem is given by the rivet nuts that is an already made fold and when it is pressed, it remains still in the hole that is located. There are lots of tools for the placement of rivet nuts especially manual ones.

Our construction numbered 0101 can be used manually or be placed in drills. The philosophy of this tool is very simple. Firstly, we put a screw at the lathe that has the shape of a hexagon at the back side in order to be able to be placed at the tools. Rotating the screw with the help of two thrust bearings, the screw spins without moving as a result the nut moves as well that is located on the screw.

This system is placed in the tube that we made on the lathe of 52mm width. On the nut, there is a keyway in which there are two stable screws which are attached to the cylinder. Therefore, when the screw spins with the hexagon part, the nut is not able to be spun so it is dragged into the cylinder forward and backward accordingly whether we are screwing or unscrewing.

In front of the nut, there is a spot where the proper adaptor enters according to the size of the rivet nuts we enter.

In our case, we made an adaptor to be able to place the rivet nuts of m4, m5, m6, m8, m10 and m12. Although, our tool is very convenient in use, we believe that if we used a hydraulic tool, it would be better.